銷(xiāo)售中心

(Tender Quatation) Sales center

|

標簽模塊

64/110kV電纜技術(shù)

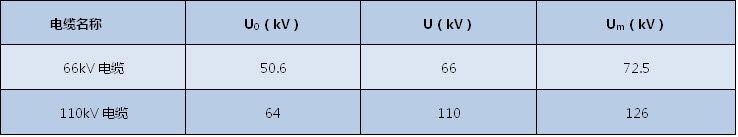

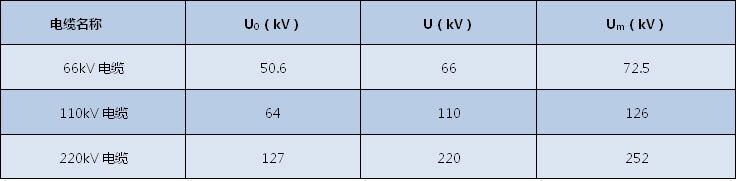

額定電壓64/110kV交聯(lián)聚乙烯絕緣皺紋鋁套聚(氯)乙烯護套電力電纜 一、產(chǎn)品執行標準 50/66kV: IEC 60840 64/110 kV: GB/T11017 IEC 60840 76/132 kV: AS/NZS 1429.2 二、使用條件 2.1 使用場(chǎng)合 適用于室內、隧道、管道等場(chǎng)所敷設,可承受壓力作用,并能承受一定的牽引力,電纜具有可靠的徑向阻水功能。ZC-YJLW02、ZR-YJLW02-Z、適用于有防火要求的場(chǎng)所敷設,FY-YJLW02-Z、FY-YJLW03-Z適用于有防蟻要求的場(chǎng)所敷設; 2.2 電力系統額定電壓 電纜允許的額定電壓U0、U、Um值如下:

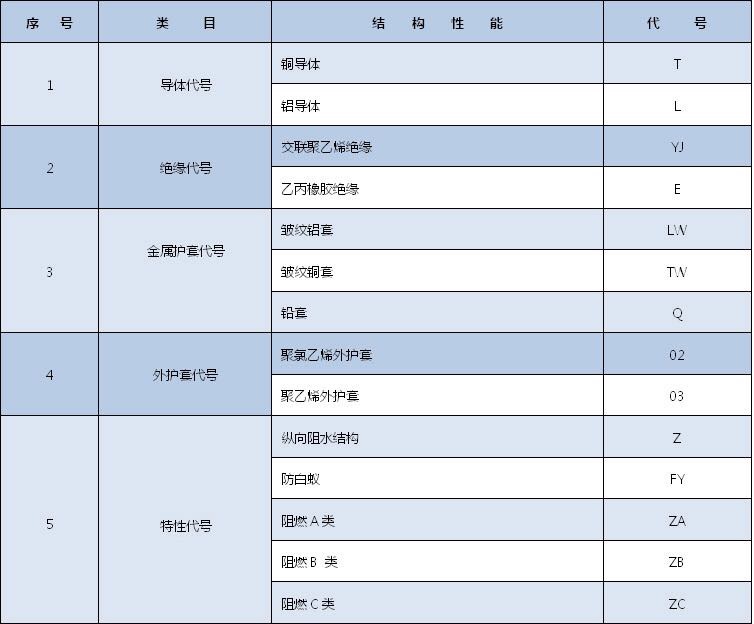

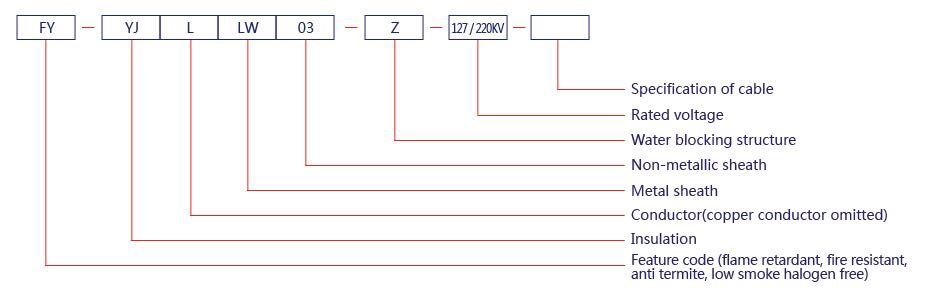

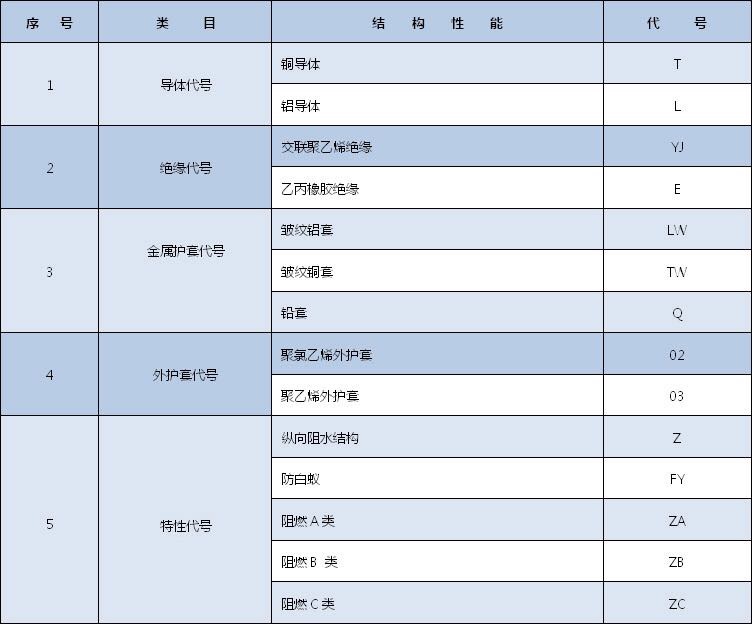

表中:U0:電纜設計用的導體與屏蔽或金屬屏蔽之間的額定電壓(相電壓) U:電纜設計時(shí)用的導體之間的額定電壓(線(xiàn)電壓) Um:設備最高電壓(使用設備的系統最高電壓的最大值) 2.3 頻率:49~61Hz 2.4 電纜導體最高額定工作溫度:90℃。 2.5 電纜導體短路時(shí)最高額定工作溫度(短路時(shí)間不超過(guò)5s):250℃。 2.6系統中性點(diǎn)接地方式: 66kV電纜:經(jīng)消弧線(xiàn)圈接地。 110~220kV電纜:直接接地系統。 三、電纜型號和產(chǎn)品表示方法 3.1 代號表示

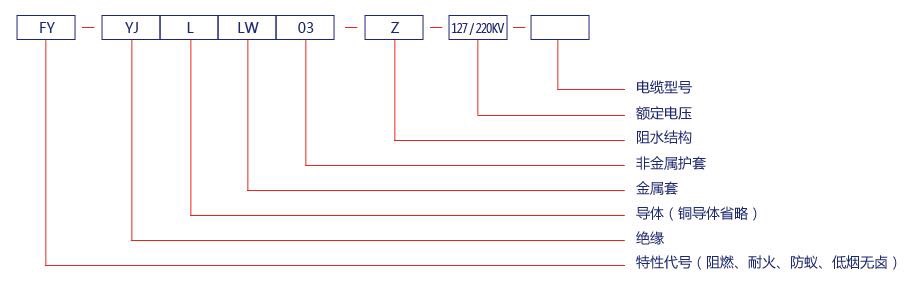

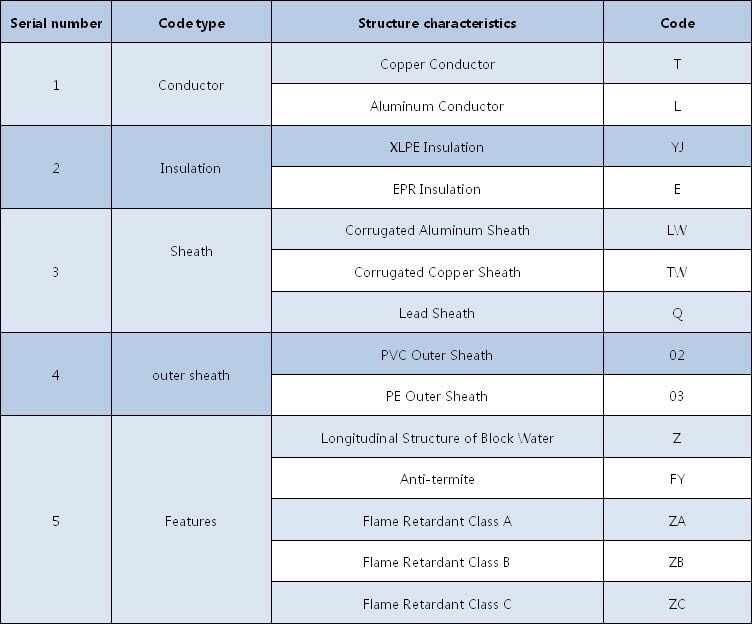

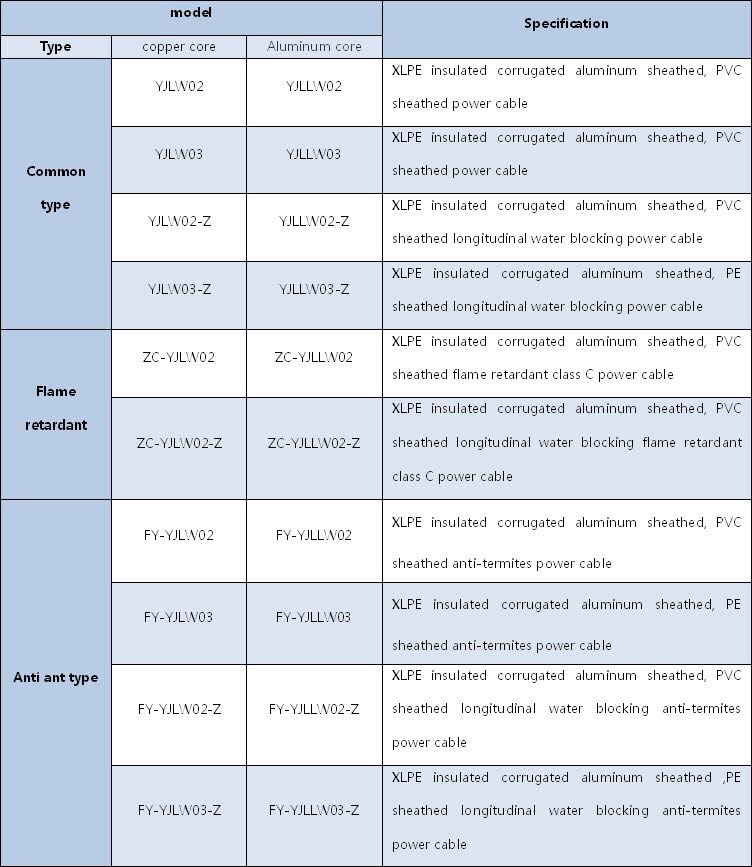

3.2 產(chǎn)品型號

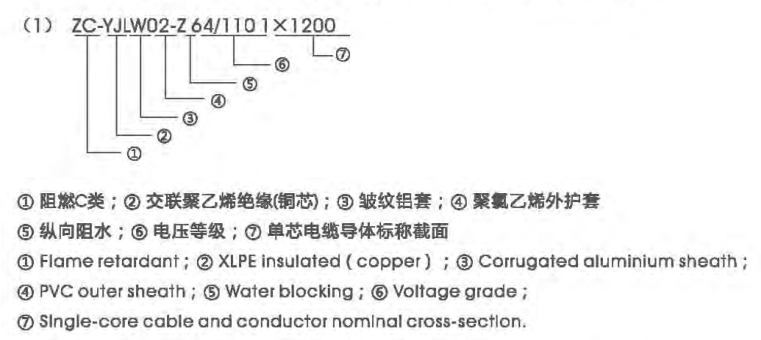

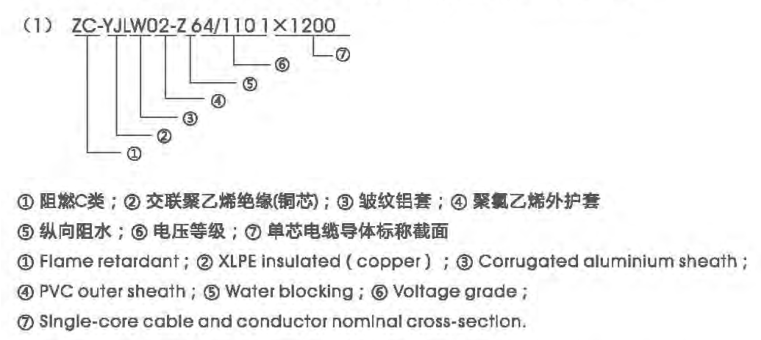

3.3 產(chǎn)品表示方法

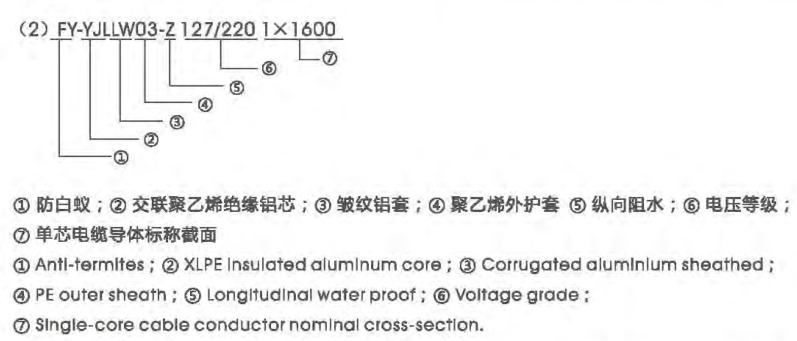

電纜型號依次由特性代號、絕緣、導體、金屬套、非金屬護套、阻水結構的代號、額定電壓)、規格(芯數、標稱(chēng)截面)及標準編號表示 例如: 3.3.1 ZC-YJ LW 02-Z-64/110KV-1*1200 ZC……………………………………………………………阻燃C類(lèi) YJ…………………………………………………………….交聯(lián)聚乙烯絕緣(銅芯) LW…………………………………………………………..皺紋鋁套 02……………………………………………………………聚氯乙烯護套 Z……………………………………………………………..縱向阻水 64/110KV……………………………………………….電壓等級 1*1000…………………………………………………..單芯電纜導體標稱(chēng)截面

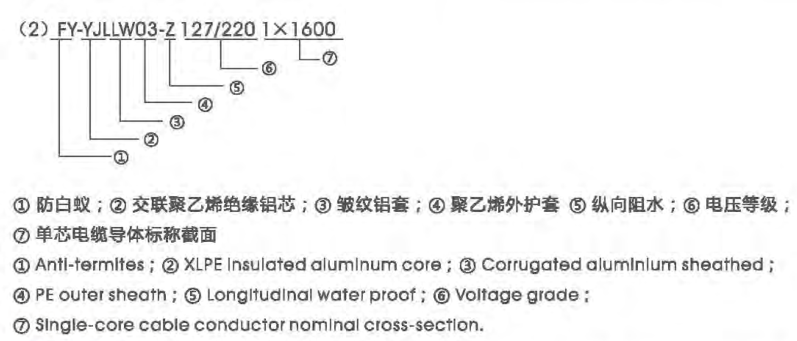

產(chǎn)品表示方法:額定電壓64/110KV、單芯、銅導體標稱(chēng)截面1200mm2、交聯(lián)聚乙烯絕緣皺紋鋁套聚氯乙烯護套縱向阻水阻燃C類(lèi)電力電纜 3.3.2 FY-YJ L LW 03-Z-127/220KV-1*1600 FY…………………………………………………….防白蟻 YJ……………………………………………………..交聯(lián)聚乙烯絕緣 L………………………………………………………鋁芯 LW……………………………………………………皺紋鋁套 03…………………………………………………….聚乙烯外護套 Z………………………………………………………縱向阻水 127/220KV………………………………………電壓等級 1*1600……………………………………………單芯電纜導體標稱(chēng)截面

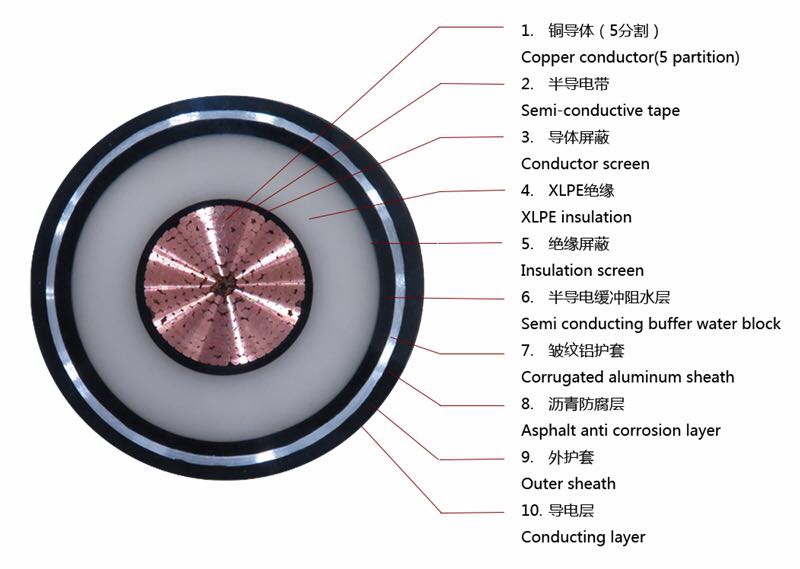

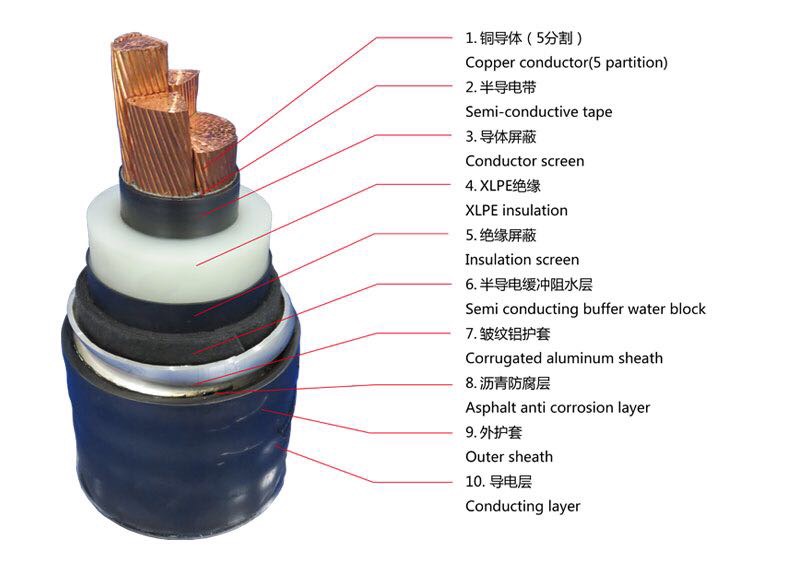

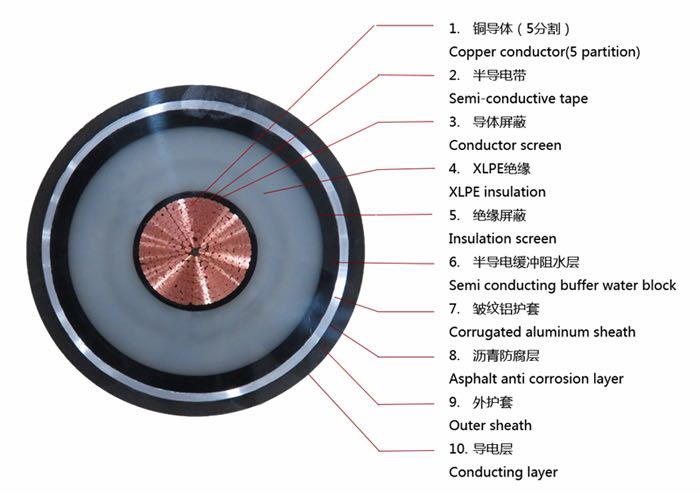

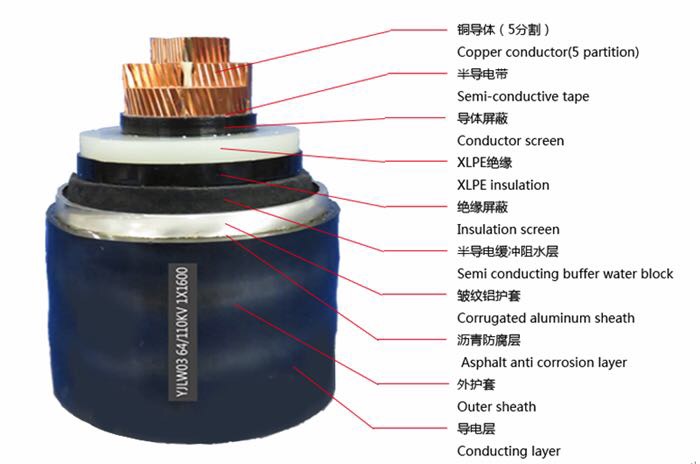

產(chǎn)品表示方法:額定電壓127/2200KV、單芯、鋁導體標稱(chēng)截面1600mm2、交聯(lián)聚乙烯絕緣皺紋鋁套聚乙烯護套縱向阻水防白蟻電力電纜 四、產(chǎn)品結構 4.1 產(chǎn)品結構示意圖

規格型號YJLW03-64/110KV-1*1600mm2

規格型號:YJLW03-64/110KV-1*1600mm2 4.2 產(chǎn)品結構 4.2.1 導體 導體材料采用銅芯緊壓圓形導體或扇形分割導體。導體標稱(chēng)截面積大于或等于800mm2時(shí),應采用分割導體結構,其結構和直流電阻應符合GB/Z 18890規定。 標稱(chēng)截面630mm2及以下電纜銅導體中的單線(xiàn)應不少于53根,標稱(chēng)截面800 mm2~1600mm2電纜銅分割導體中的單線(xiàn)應不少于170根,標稱(chēng)截面1800mm2及以上電纜銅分割導體中的單線(xiàn)應不少于265根。 導體的表面應光潔、無(wú)油污、無(wú)損傷屏蔽及絕緣的毛刺、銳邊以及凸起或斷裂的單線(xiàn); 4.2.2 導體屏蔽和絕緣屏蔽 導體屏蔽應由半導電包帶和擠出半導電層組成,其厚度近似值為2.0mm,其中擠包半導電層厚度近似值為1.5mm。擠包半導電層應均勻地包覆在半導電包帶外,并牢固地粘在絕緣層上。半導電層與絕緣層的交界面應光滑,無(wú)明顯絞線(xiàn)凸紋、尖角、顆粒、燒焦或擦傷痕跡。 4.2.3 絕緣 絕緣材料應為進(jìn)口超凈化可交聯(lián)聚乙烯料,其性能應符合GB/Z 18890的規定。絕緣層的標稱(chēng)厚度應符合GB/Z 18890的規定,絕緣平均厚度與標稱(chēng)值應為正公差,其公差不大于其標稱(chēng)值的10%+0.1mm。 4.2.4 絕緣屏蔽 絕緣屏蔽為擠包半導電層,其厚度近似值為1.0mm絕緣屏蔽應均勻地包覆在絕緣表面,并牢固地粘附在絕緣層上。絕緣屏蔽的表面以及其與絕緣層的交界面應光滑,無(wú)尖角、顆粒、燒焦或擦傷的痕跡。 4.2.5 防水層 徑向防水層宜選用金屬套,或采用綜合防水層。絕緣屏蔽與金屬套間應有縱向阻水結構,縱向阻水結構應由半導電阻水膨脹帶繞包而成,半導電阻水帶應繞包緊密、平整、無(wú)擦傷。 4.2.6 金屬屏蔽 金屬屏蔽可用銅絲編織帶、銅帶或金屬套等制作。 金屬屏蔽、金屬套截面應滿(mǎn)足系統短路容量的要求。當金屬套的截面不滿(mǎn)足要求時(shí),必須通過(guò)增加金屬套厚度或增加銅線(xiàn)屏蔽等方式來(lái)滿(mǎn)足。 4.2.7 金屬套 金屬套可為鉛套或皺紋鋁套,皺紋鋁套與鉛套均應符合GB/Z 18890的規定。鉛套應采用符合JB/T 5268.2規定的鉛合金; 皺紋鋁套應采用純度不小于99.6%的鋁材制造,鋁帶的伸長(cháng)率應不小于16%。焊接皺紋鋁套不得有圓周方向的焊縫,焊縫內壁應平整,焊縫強度須不小于鋁套強度,不得有明顯突起。 4.2.8 瀝青涂層 金屬套表面應有電纜瀝青或熱熔膠防蝕層,涂覆在金屬套上的防腐層應粘著(zhù)良好,均勻完整,采用的電纜瀝青應符合SH 0001的規定。 4.2.9 非金屬外護套 采用單層護套結構時(shí),應采用高密度聚乙烯(HDPE)、聚氯乙烯(PVC)材料 。外護套的性能、厚度及絕緣水平應符合GB/Z 18890的規定,表面應有不易脫落的連續性完好的導電層,外護套應有良好的防腐蝕、防蟻、防潮和阻燃性能;隧道內電纜非金屬外護套應采用低煙低鹵阻燃料,燃燒試驗應取得國家消防部門(mén)認可的試驗報告。 外護套需增加“退滅蟲(chóng)”(“Termigon”)或“退敵蟲(chóng)”防蟻護層時(shí),采用雙層護套結構,其中內層護套應采用高密度聚乙烯(HDPE)護套料,外層護套應采用“退滅蟲(chóng)”(“Termigon”) 或“退敵蟲(chóng)”防蟻護套料。 內層高密度聚乙烯護套厚度應為3.0~3.5mm,外層防蟻護套厚度應為2.0±0.1mm。內層高密度聚乙烯宜選用紅色添加劑,以示和外層防蟻護套區別。防蟻護套應具有良好的抗腐蝕性(尤其是螞蟻分泌的甲酸)、耐磨性和彈性。表面應具有較高的光潔度。 五、吊裝、貯存、運輸 5.1 吊裝電纜應用滿(mǎn)足重量要求的起重機及鋼纜吊裝,嚴禁幾盤(pán)同時(shí)吊裝,嚴禁從高處扔下裝有電纜的電纜盤(pán),嚴禁機械損傷電纜,吊裝時(shí)不得磕碰、吊斜,起吊點(diǎn)要正確,要輕吊輕放。 5.2 電纜盤(pán)不允許平放或溜放,電纜附件應避免在露天存放,電纜及附件應避免接觸有腐蝕性的物質(zhì),應采取必要的防火措施。并有專(zhuān)人經(jīng)常巡視,防止因意外情況造成電纜及附件受到損傷。 5.3 裝在車(chē)、船等運輸工具上的電纜盤(pán)必須平穩放置,采用合適方法固定(如線(xiàn)盤(pán)托),防止互相碰撞或翻倒。 5.4 電纜盤(pán)(不論有無(wú)托架)放置的位置要平整,不得存放于大于5度的斜面上。電纜盤(pán)側板上標有"電纜盤(pán)滾動(dòng)方向"和"牽引頭拉出方向";,牽引頭拉出方向與放線(xiàn)方向一致,放線(xiàn)前,應確認無(wú)誤。 64/110kV cable

Rated voltage 64kV/110kVXLPE insulated corrugated aluminum PE(PVC) sheathed power cable products introduction 1 Product Implementation standards 50/66kV: IEC 60840 64/110 kV: GB/T11017 IEC 60840 76/132 kV: AS/NZS 1429.2 127/220 kV: GB/Z 18890 IEC 62067 2 The use of conditions: 2.1 Use Occasions Suitable for laying indoors, in tunnel, pipeline and other places, can bear the pressure, and can bear a certain traction, the cable has a reliable radial water resistance function. ZR-YJLW02-Z, ZC-YJLW02, applicable to the installation of fire requirements of the premises, FY-YJLW03-Z, FY-YJLW02-Z suitable for the installation of the requirements of the site where the ants; 2.2Rated Voltage in Power System Allowable rated voltage value of cable U0、U、Um is as follows:

Table: U0:The rated voltage (phase voltage) between a conductor and a shield or a metal shield for the design of a cable. U:Rated voltage (line voltage) between conductors used in cable design Um:Equipment maximum voltage the maximum value of the highest voltage system using equipment 2.3 Frequency: 49 ~ 61Hz 2.4 The maximum rated operating temperature of the cable conductor: 90. 2.5 The maximum rated operating temperature of the short circuit of the cable conductor (short circuit time is not more than 5S): 250. 2.6 System neutral grounding mode: 66kV cable: grounding through arc suppression coil. 110 ~ 220kV cable: direct grounding system. Cable type and description 3.1 Code

3.2 Type

3.3 Product Description

The cable model is composed of characteristic code, insulation, conductor, metal sheath, non-metallic sheath , water blocking structure and rated voltage), specifications (core, the nominal cross-section) and standard code. For example: 3.3.1 ZC-YJLW 02-Z-64/110KV-1*1200 ZC……………………………………………………….Flame retardant C class YJ………………………………………………………..XLPE insulated T………………………………………………………...copper conductor( Omission) LW………………………………………………….…..Corrugated aluminum sheath 02……………………………………………………....PVC outer sheath Z…………………………………………………………Longistudinal structure of Block Water 64/110K……………………………………………..Voltage grade 1*1200………………………………………..…….Single core and conductor nominal cross-section

Cable specification: Rate voltage 64/110kV,single core , copper conductor nominal cross section 1200mm2, XLPE insulated corrugated aluminum sheathed longitudinal blocking water flame retardant class C PVC sheathed power cable. 3.3.2 FY-YJ L LW 03-Z-127/220KV-1*1600 FY…………………………………………………..Anti-termites YJ…………………………………………………...XLPE insulated L…………………………………………………….aluminum core LW…………………………………………..…….Corrugated aluminum sheath 03………………………………………………….PE outer sheath Z………………………………………………..….Longitudinal water proof 127/220KV………………………………..….Voltage grade 1*1600……………………………………..….Single core and conductor nominal cross-section

Cable specification: Rate voltage 127/220kV, single core, Aluminum conductor nominal cross section 1600mm2, XLPE insulated corrugated aluminum sheathed longitudinal water proof flame retardant PE sheathed power cable. 4 Product Structure 4.1 Product Structure Diagrams

Specification Model: YJLW03-64/110KV-1*1600mm2

Specification Model: YJLW03-64/110KV-1*1600mm2 4.2 Product Structure 4.2.1 Conductor Conductor material using copper core tight circular conductor or sector split conductor. When the nominal cross-sectional area of the conductor is greater than or equal to 800mm2, the split conductor structure should be adopted, and the structure and the DC resistance should be in accordance with the provisions of GB/Z 18890. Nominal cross section 630mm2 and following copper conductor cables line shall not be less than 53 root, nominal cross-sectional area of 800 mm2 to 1600mm2 copper cable segmentation conductor line shall not be less than 170 root, the nominal section 1800mm2 and above cable copper segmentation single conductor shall not be less than 265 root. The surface of the conductor shall be smooth, free from oil pollution, no damage to the shield and the insulation of the burr, sharp edge and a convex or broken line; 4.2.2 Conductor Shielding and Insulation Shielding The conductor shield should be composed of a semi conductive package and an extruded semi conductive layer, the thickness of which is 2.0mm, and the thickness of the extruded semi conductive layer is 1.5mm. The extruded semi conductive layer should be evenly coated on the semi conductive tape outside, and firmly adhered to the insulating layer. The semi conductive layer and the insulating layer of the interface should be smooth, no obvious strand, sharp corners, strand particles, burnt or scratches. 4.2.3 Insulation Insulation material should be imported super purified to cross linked polyethylene material, its performance should be in accordance with the provisions of GB/Z 18890. The nominal thickness of the insulating layer shall be in accordance with the provisions of GB/Z 18890, The average thickness of the insulation and the nominal value shall be the positive tolerance, the positive tolerance is not greater than the nominal value of 10%+0.1mm.。 4.2.4 Insulation Shielding The insulation shield is an extruded semi conductive layer, the thickness of which is similar to that of the 1.0mm insulation shield, which is evenly coated on the insulating surface and firmly adhered to the insulating layer. The surface of the insulation shielding and the interface between the insulation shield and the insulation layer should be smooth, with no sharp corners, particles, burnt or scratch marks。 4.2.5 Waterproof Layer The radial waterproof layer is advised to use the metal sleeve, or adopt the comprehensive waterproof layer. Insulation shield and the metal sleeve should be longitudinal resistance water structure, longitudinal resistance water structure should be semi conductive water resistance expansion tape wrapped into, semi conducting water-resistant tape should be wrapped tight, smooth and free of scratches. 4.2.6 Metal Shield The metal shielding are made by copper wire or copper tape or metal sleeve etc. Metal shielding and metal sleeve section should meet the requirement of system short circuit capacity. When the section of the metal sleeve does not meet the requirements, it must be met by increasing the thickness of the metal sleeve or increasing the copper wire shielding. 4.2.7 Metal Sleeve The metal sleeve may be a lead sheath or wrinkle aluminum sleeve, and the wrinkle aluminum sleeve and lead sheath shall comply with the provisions of GB/Z 18890. Lead should be used in accordance with the provisions of JB/T 5268.2 lead alloy; Wrinkle aluminum sleeve shall be made of aluminum with a purity of not less than 99.6%, the elongation of aluminum strip shall be not less than 16%. Welded corrugated aluminum sleeve shall not have circumferential direction of the weld, the inner wall of the weld shall be flat, the strength of the weld shall be not less than the strength of the aluminum cover, no obvious protrusion. 4.2.8 Asphalt Coating Set of metal surface should be cable asphalt or hot melt adhesive anti-corrosion coating, anticorrosive coating on the metal sleeve layer should be good adhesion, complete and evenly, the bitumen cable should be in accordance with the provisions of SH 0001.。 4.2.9 Non Metallic Sheath High density polyethylene (HDPE) and polyvinyl chloride (PVC) materials should be used in the single layer jacket structure. The performance, thickness and insulation level of the outer sheath shall be in accordance with the provisions of GB/Z 18890, The surface should contain a conductive layer which is not easy to fall off and good continuity, outer sheath should have good anti-corrosion, anti ant, damp proof and flame retardant properties; Low smoke and low halogen resistance fuel should be used in the non metallic sheath of the cable in the tunnel. and combustion test should be achieved national fire department approval of the test report. The outer sheath to increase the "pest control" ("Termigon") or "tuidi bug" anti termite sheath, should adopt double sleeve structure,. The inner sheath should use high density polyethylene (HDPE) sheath material, The outer jacket should be used "pest control" ("Termigon") or "tuidi bug" anti termite sheath material. The inner high density polyethylene sheath thickness should be 3 ~ 3.5mm, the outer sheath thickness should be 2 + 0.1mm. The inner high density polyethylene should choose red additive, to show the difference between the outer layer and the anti - ant sheath. The anti - ant sheath should have good corrosion resistance (especially formic acid), wear resistance and elasticity. Surface should have a high degree of finish. 5 Lifting, Storage and Transportation 5.1 Hoisting cable applications meet the weight of crane and cable hoisting, prohibited several dishes at the same time, hoisting, is strictly prohibited from throwing height with cable of cable tray, non mechanical damage to the cables, lifting shall not bump, oblique hanging and lifting points to correct, to light hanging with care. 5.2 Cable tray does not allow flat or rolling, cable accessories should avoid storing in the open air, cables and accessories should avoid contact with corrosive substances, should take the necessary precautions against fire. And there is a regular inspection, to prevent accidents caused by cable and accessories damage. 5.3 Installed in vehicles, ships and other means of transport of cable plate must be placed on a smooth, using appropriate fixation methods (such as line tray) to prevent colliding or overturned. 5.4 The position of the cable tray (whether or not there is no bracket) to be level, and shall not be stored on the inclined plane of more than 5 degrees. Cable reel side superscript "cable disc rolling direction" and "traction head out of the direction, traction head out of the direction and the line direction, placed in front of the line should be the confirmation. 127/220kV電纜技術(shù)

南洋電纜額定電壓127/220kV交聯(lián)聚乙烯絕緣皺紋鋁套聚(氯)乙烯護套電力電纜 一、產(chǎn)品執行標準 50/66kV: IEC 60840 64/110 kV: GB/T11017 IEC 60840 76/132 kV: AS/NZS 1429.2 127/220 kV: GB/Z 18890 IEC 62067 二、使用條件 2.1 使用場(chǎng)合 適用于室內、隧道、管道等場(chǎng)所敷設,可承受壓力作用,并能承受一定的牽引力,電纜具有可靠的徑向阻水功能。ZC-YJLW02、ZR-YJLW02-Z適用于有防火要求的場(chǎng)所敷設,FY-YJLW02-Z、FY-YJLW03-Z適用于有防蟻要求的場(chǎng)所敷設; 2.2 電力系統額定電壓 電纜允許的額定電壓U0、U、Um值如下:

表中:U0:電纜設計用的導體與屏蔽或金屬屏蔽之間的額定電壓(相電壓) U:電纜設計時(shí)用的導體之間的額定電壓(線(xiàn)電壓) Um:設備最高電壓(使用設備的系統最高電壓的最大值) 2.3 頻率:49~61Hz 2.4 電纜導體最高額定工作溫度:90℃。 2.5 電纜導體短路時(shí)最高額定工作溫度(短路時(shí)間不超過(guò)5s):250℃。 2.6系統中性點(diǎn)接地方式: 66kV電纜:經(jīng)消弧線(xiàn)圈接地。 110~220kV電纜:直接接地系統。 三、電纜型號和產(chǎn)品表示方法 3.1 代號表示

3.2 產(chǎn)品型號

3.3 產(chǎn)品表示方法

電纜型號依次由特性代號、絕緣、導體、金屬套、非金屬護套、阻水結構的代號、額定電壓)、規格(芯數、標稱(chēng)截面)及標準編號表示 例如: 3.3.1 ZC-YJ LW 02-Z-64/110KV-1*1200 ZC……………………………………………………阻燃C類(lèi) YJ…………………………………………………….交聯(lián)聚乙烯絕緣(銅芯) LW…………………………………………………..皺紋鋁套 02…………………………………………………..聚氯乙烯護套 Z…………………………………………………….縱向阻水 64/110K………………………………………...電壓等級 1*1200…………………………………………..單芯電纜導體標稱(chēng)截面

產(chǎn)品表示方法:額定電壓64/110KV、單芯、銅導體標稱(chēng)截面1200mm2、交聯(lián)聚乙烯絕緣皺紋鋁套聚氯乙烯護套縱向阻水阻燃C類(lèi)電力電纜 3.3.2 FY-YJ L LW 03-Z-127/220KV-1*1600 FY…………………………………………………….防白蟻 YJ……………………………………………………..交聯(lián)聚乙烯絕緣 L………………………………………………………鋁芯 LW……………………………………………………皺紋鋁套 03…………………………………………………….聚乙烯外護套 Z………………………………………………………縱向阻水 127/220KV………………………………………電壓等級 1*1600……………………………………………單芯電纜導體標稱(chēng)截面

產(chǎn)品表示方法:額定電壓127/2200KV、單芯、鋁導體標稱(chēng)截面1600mm2、交聯(lián)聚乙烯絕緣皺紋鋁套聚乙烯護套縱向阻水防白蟻電力電纜 四、產(chǎn)品結構 4.1 產(chǎn)品結構示意圖

規格型號: YJLW03-127/220KV-1*2500mm2

規格型號: YJLW03-127/220KV-1*1600mm2 4.2 產(chǎn)品結構 4.2.1 導體 導體材料采用銅芯緊壓圓形導體或扇形分割導體。導體標稱(chēng)截面積大于或等于800mm2時(shí),應采用分割導體結構,其結構和直流電阻應符合GB/Z 18890規定。 標稱(chēng)截面630mm2及以下電纜銅導體中的單線(xiàn)應不少于53根,標稱(chēng)截面800 mm2~1600mm2電纜銅分割導體中的單線(xiàn)應不少于170根,標稱(chēng)截面1800mm2及以上電纜銅分割導體中的單線(xiàn)應不少于265根。 導體的表面應光潔、無(wú)油污、無(wú)損傷屏蔽及絕緣的毛刺、銳邊以及凸起或斷裂的單線(xiàn); 4.2.2 導體屏蔽和絕緣屏蔽 導體屏蔽應由半導電包帶和擠出半導電層組成,其厚度近似值為2.0mm,其中擠包半導電層厚度近似值為1.5mm。擠包半導電層應均勻地包覆在半導電包帶外,并牢固地粘在絕緣層上。半導電層與絕緣層的交界面應光滑,無(wú)明顯絞線(xiàn)凸紋、尖角、顆粒、燒焦或擦傷痕跡。 4.2.3 絕緣 絕緣材料應為進(jìn)口超凈化可交聯(lián)聚乙烯料,其性能應符合GB/Z 18890的規定。絕緣層的標稱(chēng)厚度應符合GB/Z 18890的規定,絕緣平均厚度與標稱(chēng)值應為正公差,其公差不大于其標稱(chēng)值的10%+0.1mm。 4.2.4 絕緣屏蔽 絕緣屏蔽為擠包半導電層,其厚度近似值為1.0mm絕緣屏蔽應均勻地包覆在絕緣表面,并牢固地粘附在絕緣層上。絕緣屏蔽的表面以及其與絕緣層的交界面應光滑,無(wú)尖角、顆粒、燒焦或擦傷的痕跡。 4.2.5 防水層 徑向防水層宜選用金屬套,或采用綜合防水層。絕緣屏蔽與金屬套間應有縱向阻水結構,縱向阻水結構應由半導電阻水膨脹帶繞包而成,半導電阻水帶應繞包緊密、平整、無(wú)擦傷。 4.2.6 金屬屏蔽 金屬屏蔽可用銅絲編織帶、銅帶或金屬套等制作。 金屬屏蔽、金屬套截面應滿(mǎn)足系統短路容量的要求。當金屬套的截面不滿(mǎn)足要求時(shí),必須通過(guò)增加金屬套厚度或增加銅線(xiàn)屏蔽等方式來(lái)滿(mǎn)足。 4.2.7 金屬套 金屬套可為鉛套或皺紋鋁套,皺紋鋁套與鉛套均應符合GB/Z 18890的規定。鉛套應采用符合JB/T 5268.2規定的鉛合金; 皺紋鋁套應采用純度不小于99.6%的鋁材制造,鋁帶的伸長(cháng)率應不小于16%。焊接皺紋鋁套不得有圓周方向的焊縫,焊縫內壁應平整,焊縫強度須不小于鋁套強度,不得有明顯突起。 4.2.8 瀝青涂層 金屬套表面應有電纜瀝青或熱熔膠防蝕層,涂覆在金屬套上的防腐層應粘著(zhù)良好,均勻完整,采用的電纜瀝青應符合SH 0001的規定。 4.2.9 非金屬外護套 采用單層護套結構時(shí),應采用高密度聚乙烯(HDPE)、聚氯乙烯(PVC)材料 。外護套的性能、厚度及絕緣水平應符合GB/Z 18890的規定,表面應有不易脫落的連續性完好的導電層,外護套應有良好的防腐蝕、防蟻、防潮和阻燃性能;隧道內電纜非金屬外護套應采用低煙低鹵阻燃料,燃燒試驗應取得國家消防部門(mén)認可的試驗報告。 外護套需增加“退滅蟲(chóng)”(“Termigon”)或“退敵蟲(chóng)”防蟻護層時(shí),采用雙層護套結構,其中內層護套應采用高密度聚乙烯(HDPE)護套料,外層護套應采用“退滅蟲(chóng)”(“Termigon”) 或“退敵蟲(chóng)”防蟻護套料。 內層高密度聚乙烯護套厚度應為3.0~3.5mm,外層防蟻護套厚度應為2.0±0.1mm。內層高密度聚乙烯宜選用紅色添加劑,以示和外層防蟻護套區別。防蟻護套應具有良好的抗腐蝕性(尤其是螞蟻分泌的甲酸)、耐磨性和彈性。表面應具有較高的光潔度。 五、吊裝、貯存、運輸 5.1 吊裝電纜應用滿(mǎn)足重量要求的起重機及鋼纜吊裝,嚴禁幾盤(pán)同時(shí)吊裝,嚴禁從高處扔下裝有電纜的電纜盤(pán),嚴禁機械損傷電纜,吊裝時(shí)不得磕碰、吊斜,起吊點(diǎn)要正確,要輕吊輕放。 5.2 電纜盤(pán)不允許平放或溜放,電纜附件應避免在露天存放,電纜及附件應避免接觸有腐蝕性的物質(zhì),應采取必要的防火措施。并有專(zhuān)人經(jīng)常巡視,防止因意外情況造成電纜及附件受到損傷。 5.3 裝在車(chē)、船等運輸工具上的電纜盤(pán)必須平穩放置,采用合適方法固定(如線(xiàn)盤(pán)托),防止互相碰撞或翻倒。 5.4 電纜盤(pán)(不論有無(wú)托架)放置的位置要平整,不得存放于大于5度的斜面上。電纜盤(pán)側板上標有“電纜盤(pán)滾動(dòng)方向”和“牽引頭拉出方向”,牽引頭拉出方向與放線(xiàn)方向一致,放線(xiàn)前,應確認無(wú)誤。 127~220kVcable

Rated voltage 127kV/220kVXLPE insulated corrugated aluminum PE(PVC) sheathed power cable products introduction 1 Product Implementation standards 50/66kV: IEC 60840 64/110 kV: GB/T11017 IEC 60840 76/132 kV: AS/NZS 1429.2 127/220 kV: GB/Z 18890 IEC 62067 2 The use of conditions: 2.1 Use Occasions Suitable for laying indoors, in tunnel, pipeline and other places, can bear the pressure, and can bear a certain traction, the cable has a reliable radial water resistance function. ZC-YJLW02-Z, ZC-YJLW02, applicable to the installation of fire requirements of the premises, FY-YJLW03-Z, FY-YJLW02-Z suitable for the installation of the requirements of the site where the ants; 2.2Rated Voltage in Power System Allowable rated voltage value of cable U0、U、Um is as follows:

Table: U0:The rated voltage (phase voltage) between a conductor and a shield or a metal shield for the design of a cable. U: Rated voltage (line voltage) between conductors used in cable design Um: Equipment maximum voltage the maximum value of the highest voltage system using equipment 2.3 Frequency: 49 ~ 61Hz 2.4 The maximum rated operating temperature of the cable conductor: 90. 2.5 The maximum rated operating temperature of the short circuit of the cable conductor (short circuit time is not more than 5S): 250. 2.6 System neutral grounding mode: 66kV cable: grounding through arc suppression coil. 110 ~ 220kV cable: direct grounding system. Cable type and description 3.1 Code

3.2 Type

3.3 Product Description

The cable model is composed of characteristic code, insulation, conductor, metal sheath, non-metallic sheath , water blocking structure and rated voltage), specifications (core, the nominal cross-section) and standard code. For example: 3.3.1 ZC-YJLW 02-Z-64/110KV-1*1200 ZC……………………………………………………….Flame retardant C class YJ………………………………………………………..XLPE insulated T………………………………………………………...copper conductor( Omission) LW………………………………………………….…..Corrugated aluminum sheath 02……………………………………………………....PVC outer sheath Z…………………………………………………………Longistudinal structure of Block Water 64/110K……………………………………………..Voltage grade 1*1200………………………………………..…….Single core and conductor nominal cross-section

Cable specification: Rate voltage 64/110kV,single core , copper conductor nominal cross section 1200mm2, XLPE insulated corrugated aluminum sheathed longitudinal blocking water flame retardant class C PVC sheathed power cable. 3.3.2 FY-YJ L LW 03-Z-127/220KV-1*1600 FY…………………………………………………..Anti-termites YJ…………………………………………………...XLPE insulated L…………………………………………………….aluminum core LW…………………………………………..…….Corrugated aluminum sheath 03………………………………………………….PE outer sheath Z………………………………………………..….Longitudinal water proof 127/220KV………………………………..….Voltage grade 1*1600……………………………………..….Single core and conductor nominal cross-section

Cable specification: Rate voltage 127/220kV, single core, Aluminum conductor nominal cross section 1600mm2, XLPE insulated corrugated aluminum sheathed longitudinal water proof flame retardant PE sheathed power cable. 4 Product Structure 4.1 Product Structure Diagrams

Specification Model:YJLW03-127/220KV-1*2500mm2

Specification Model:YJLW03-127/220KV-1*1600mm2 4.2 Product Structure 4.2.1 Conductor Conductor material using copper core tight circular conductor or sector split conductor. When the nominal cross-sectional area of the conductor is greater than or equal to 800mm2, the split conductor structure should be adopted, and the structure and the DC resistance should be in accordance with the provisions of GB/Z 18890. Nominal cross section 630mm2 and following copper conductor cables line shall not be less than 53 root, nominal cross-sectional area of 800 mm2 to 1600mm2 copper cable segmentation conductor line shall not be less than 170 root, the nominal section 1800mm2 and above cable copper segmentation single conductor shall not be less than 265 root. The surface of the conductor shall be smooth, free from oil pollution, no damage to the shield and the insulation of the burr, sharp edge and a convex or broken line; 4.2.2 Conductor Shielding and Insulation Shielding The conductor shield should be composed of a semi conductive package and an extruded semi conductive layer, the thickness of which is 2.0mm, and the thickness of the extruded semi conductive layer is 1.5mm. The extruded semi conductive layer should be evenly coated on the semi conductive tape outside, and firmly adhered to the insulating layer. The semi conductive layer and the insulating layer of the interface should be smooth, no obvious strand, sharp corners, strand particles, burnt or scratches. 4.2.3 Insulation Insulation material should be imported super purified to cross linked polyethylene material, its performance should be in accordance with the provisions of GB/Z 18890. The nominal thickness of the insulating layer shall be in accordance with the provisions of GB/Z 18890, The average thickness of the insulation and the nominal value shall be the positive tolerance, the positive tolerance is not greater than the nominal value of 10%+0.1mm.。 4.2.4 Insulation Shielding The insulation shield is an extruded semi conductive layer, the thickness of which is similar to that of the 1.0mm insulation shield, which is evenly coated on the insulating surface and firmly adhered to the insulating layer. The surface of the insulation shielding and the interface between the insulation shield and the insulation layer should be smooth, with no sharp corners, particles, burnt or scratch marks. 4.2.5 Waterproof Layer The radial waterproof layer is advised to use the metal sleeve, or adopt the comprehensive waterproof layer. Insulation shield and the metal sleeve should be longitudinal resistance water structure, longitudinal resistance water structure should be semi conductive water resistance expansion tape wrapped into, semi conducting water-resistant tape should be wrapped tight, smooth and free of scratches. 4.2.6 Metal Shield The metal shielding are made by copper wire or copper tape or metal sleeve etc.. Metal shielding and metal sleeve section should meet the requirement of system short circuit capacity. When the section of the metal sleeve does not meet the requirements, it must be met by increasing the thickness of the metal sleeve or increasing the copper wire shielding. 4.2.7 Metal Sleeve The metal sleeve may be a lead sheath or wrinkle aluminum sleeve, and the wrinkle aluminum sleeve and lead sheath shall comply with the provisions of GB/Z 18890. Lead should be used in accordance with the provisions of JB/T 5268.2 lead alloy; Wrinkle aluminum sleeve shall be made of aluminum with a purity of not less than 99.6%, the elongation of aluminum strip shall be not less than 16%. Welded corrugated aluminum sleeve shall not have circumferential direction of the weld, the inner wall of the weld shall be flat, the strength of the weld shall be not less than the strength of the aluminum cover, no obvious protrusion. 4.2.8 Asphalt Coating Set of metal surface should be cable asphalt or hot melt adhesive anti-corrosion coating, anticorrosive coating on the metal sleeve layer should be good adhesion, complete and evenly, the bitumen cable should be in accordance with the provisions of SH 0001.。 4.2.9 Non Metallic Sheath High density polyethylene (HDPE) and polyvinyl chloride (PVC) materials should be used in the single layer jacket structure. The performance, thickness and insulation level of the outer sheath shall be in accordance with the provisions of GB/Z 18890, The surface should contain a conductive layer which is not easy to fall off and good continuity, outer sheath should have good anti-corrosion, anti ant, damp proof and flame retardant properties; Low smoke and low halogen resistance fuel should be used in the non metallic sheath of the cable in the tunnel. and combustion test should be achieved national fire department approval of the test report. The outer sheath to increase the "pest control" ("Termigon") or "tuidi bug" anti termite sheath, should adopt double sleeve structure,. The inner sheath should use high density polyethylene (HDPE) sheath material, The outer jacket should be used "pest control" ("Termigon") or "tuidi bug" anti termite sheath material. The inner high density polyethylene sheath thickness should be 3 ~ 3.5mm, the outer sheath thickness should be 2 + 0.1mm. The inner high density polyethylene should choose red additive, to show the difference between the outer layer and the anti - ant sheath. The anti - ant sheath should have good corrosion resistance (especially formic acid), wear resistance and elasticity. Surface should have a high degree of finish. 5 Lifting, Storage and Transportation 5.1 Hoisting cable applications meet the weight of crane and cable hoisting, prohibited several dishes at the same time, hoisting, is strictly prohibited from throwing height with cable of cable tray, non mechanical damage to the cables, lifting shall not bump, oblique hanging and lifting points to correct, to light hanging with care. 5.2 Cable tray does not allow flat or rolling, cable accessories should avoid storing in the open air, cables and accessories should avoid contact with corrosive substances, should take the necessary precautions against fire. And there is a regular inspection, to prevent accidents caused by cable and accessories damage. 5.3 Installed in vehicles, ships and other means of transport of cable plate must be placed on a smooth, using appropriate fixation methods (such as line tray) to prevent colliding or overturned. 5.4 The position of the cable tray (whether or not there is no bracket) to be level, and shall not be stored on the inclined plane of more than 5 degrees. Cable reel side superscript "cable disc rolling direction" and "traction head out of the direction, traction head out of the direction and the line direction, placed in front of the line should be the confirmation. 500kV電力電纜技術(shù)

南洋電纜額定電壓 500kV(Um=550kV)交聯(lián)聚乙烯絕緣皺紋鋁套聚(氯)乙烯護套電力電纜 一、 產(chǎn)品執行標準 GB/T22078.1-2008額定電壓 500kV(Um=550kV)交聯(lián)聚乙烯絕緣電力電纜及其附件電力電纜系統-試驗方法和要求 GB/T22078.2-2008額定電壓 500kV(Um=550kV)交聯(lián)聚乙烯絕緣電力電纜 GB/T22078.3-2008額定電壓 500kV(Um=550kV)交聯(lián)聚乙烯絕緣電力電纜附件 二 使用條件 2.1使用場(chǎng)合 2.1.1電纜導體最高允許溫度:正常運行時(shí)為 90℃;短路時(shí)(最長(cháng) 5s)為 250℃。 2.1.2電纜的安裝最小彎曲半徑推薦為 20 倍電纜外徑。 2.1.3電纜的使用環(huán)境主要由電纜金屬套和塑料外護套的性能確定 2.1.3.1金屬套 鉛套和皺紋鋁套除適用于一般場(chǎng)所外,特別適用于下列場(chǎng)合: —— 鉛套電纜:腐蝕較嚴重但無(wú)硝酸、醋酸、有機質(zhì)(如泥煤)及強堿性腐蝕質(zhì),且受機械力(拉力、壓力、振動(dòng)等)不大的的場(chǎng)所。 —— 皺紋鋁套電纜:腐蝕不嚴重和要求承受一定機械力的場(chǎng)所(如直接與變壓器連接,敷設在橋 梁上和豎井中等)。 2.1.3.2 塑料外護套 —— 02 型(聚氯乙烯)外護套電纜主要適用于有一般防火要求和對外護套有一定絕緣要求的高壓電纜線(xiàn)路; —— 03 型(聚乙烯)外護套電纜主要適用于對外護套絕緣要求較高的直埋敷設的高壓電纜線(xiàn)路。 如有必要用于隧道或豎井中時(shí)應采取一定的阻燃防火措施。 2.2電力系統額定電壓 電纜允許的額定電壓U0、U、Um值如下:

表中: U0:電纜設計用的導體與屏蔽或金屬屏蔽之間的額定電壓(相電壓) U:電纜設計時(shí)用的導體之間的額定電壓(線(xiàn)電壓) Um:設備最高電壓(使用設備的系統最高電壓的最大值) 三、電纜型號和產(chǎn)品表示方法 3.1 代號表示 注: 皺紋鋁護套包括擠包皺紋鋁護套和焊接皺紋鋁護套,兩種不同皺紋鋁護套的代號均為LW不作區分,但焊接皺紋鋁護套應在產(chǎn)品名稱(chēng)中明確,名稱(chēng)中未說(shuō)明焊接皺紋鋁護套的即為擠包皺紋鋁護套。皺紋銅護套和皺紋不銹鋼護套均為焊接金屬護套。 3.2 產(chǎn)品型號

3.3 產(chǎn)品表示方法

電纜型號依次由特性代號、絕緣、導體、金屬套、非金屬護套、阻水結構的代號、額定電壓)、規格(芯數、標稱(chēng)截面)及標準編號表示 3.3.1 電纜規格 額定電壓290/500KV電纜的導體截面(mm2)為800、1000、1200、(1400)、1600、(1800)、2000、(2200)、2500。其中括號內電纜規格為非優(yōu)選導體截面; 3.1.2 型號依次由絕緣、導體、金屬套、非金屬護套及阻燃特性、防白蟻、阻水結構的代號構成: 3.1.2.1 ZC-YJ LW 02-Z-290/500kV-1*1600 ZC…………..…………..阻燃C類(lèi) YJ………………………..交聯(lián)聚乙烯絕緣(銅芯) LW………….…………..皺紋鋁套 02…………..…………..聚氯乙烯護套 Z…………….…………..縱向阻水 290/500kV………….電壓等級 1*1600……….單芯電纜導體標稱(chēng)截面 產(chǎn)品表示方法:額定電壓290/500KV、單芯、銅導體標稱(chēng)截面1600mm2、交聯(lián)聚乙烯絕緣皺紋鋁套聚氯乙烯護套縱向阻水阻燃C類(lèi)電力電纜 3.1.2.2 FY-YJ L LW 03-Z-290/500KV-1*2500 FY…………..…………..防白蟻 YJ…………..……………交聯(lián)聚乙烯絕緣 L…………..…………….鋁芯 LW…………..………….皺紋鋁套 03…………..…………..聚乙烯外護套 Z…………..…………….縱向阻水 290/500KV…………電壓等級 1*2500…………..….單芯電纜導體標稱(chēng)截面 產(chǎn)品表示方法:額定電壓290/500KV、單芯、鋁導體標稱(chēng)截面2500mm2、交聯(lián)聚乙烯絕緣皺紋鋁套聚乙烯護套縱向阻水防白蟻電力電纜 3.1.2.3 FY-YJ L Q 03-Z-290/500KV-1*2000 FY…………..…………..防白蟻 YJ…………..……………交聯(lián)聚乙烯絕緣 L…………..…………….鋁芯 Q…………..……………鉛套 03…………..…………..聚乙烯外護套 Z…………..…………….縱向阻水 290/500KV………….電壓等級 1*2000…………..…..單芯電纜導體標稱(chēng)截面 產(chǎn)品表示方法:額定電壓290/500KV、單芯、鋁導體標稱(chēng)截面2000mm2、交聯(lián)聚乙烯絕緣鉛套聚乙烯護套縱向阻水防白蟻電力電纜 四、產(chǎn)品結構 4.1 產(chǎn)品結構圖

規格型號: YJLW03-Z-290/500KV-1*2500mm2

規格型號: FY-YJLW03-Z-290/500KV-1*2500mm2 4.2 產(chǎn)品結構 4.2.1 導體 電纜導體材料采用銅芯緊壓圓形導體或扇形分割導體。當導體標稱(chēng)截面積為800mm2時(shí),可任意選用緊壓導體或分割導體結構。1000mm2及以上導體則采用分割導體結構, 導體的表面光潔、無(wú)油污、無(wú)毛刺、銳邊以及凸起或斷裂的單線(xiàn); 當電纜導體標稱(chēng)截面為800mm2時(shí),導體中的單線(xiàn)根數不少于53,當標稱(chēng)截面為1000mm2~1600mm2時(shí),電纜銅分割導體中的單線(xiàn)不少于170根,標稱(chēng)截面為1800mm2及以上電纜銅分割導體中的單線(xiàn)不少于265根。 4.2.2 導體屏蔽 導體屏蔽由半導電包帶和擠出半導電層組成,其厚度近似值為2.5mm,其中擠包半導電層厚度近似值為2.0mm。 屏蔽用半導電材料采用超光滑可交聯(lián)半導電材料。擠包半導電層均勻地包覆在半導電包帶外,并牢固地粘在絕緣層上。半導電層與絕緣層的交界面光滑,無(wú)明顯絞線(xiàn)凸紋、尖角、顆粒、燒焦或擦傷痕跡。 4.2.3 絕緣 絕緣材料采用進(jìn)口超凈化可交聯(lián)聚乙烯料,絕緣平均厚度與標稱(chēng)值應為正公差,其公差不大于其標稱(chēng)值的10%+0.1mm。 4.2.4 絕緣屏蔽 絕緣屏蔽為擠包半導電層,其厚度近似值為1.0mm。絕緣屏蔽應與導體擠包屏蔽層和絕緣層一起 三層共擠。絕緣屏蔽應均勻地包覆在絕緣表面,并牢固地粘附在絕緣層上。絕緣屏蔽的表面以及其與絕緣層的交界面應光滑,無(wú)尖角、顆粒、燒焦或擦傷的痕跡。 4.2.5 緩沖層、縱向阻水結構 緩沖層:在導體半導電屏蔽層外應有緩沖層,緩沖層可采用半導電性材料或具有縱向阻水功能的半導電阻水膨脹帶繞包而成。繞包要求平整、緊實(shí)、無(wú)皺褶。 縱向阻水結構:對電纜的金屬套內間隙有縱向阻水要求時(shí),絕緣屏蔽與金屬套間應有縱向阻水結構。 縱向阻水結構由半導電阻水膨脹帶繞包而成, 半導電阻水帶繞包緊密、平整、無(wú)擦傷。 4.2.6 金屬屏蔽 金屬屏蔽可用銅絲編織帶、銅帶或金屬套等制作。 金屬屏蔽、金屬套截面應滿(mǎn)足系統短路容量的要求。當金屬套的截面不滿(mǎn)足要求時(shí),必須通過(guò)增加金屬套厚度或增加銅線(xiàn)屏蔽等方式來(lái)滿(mǎn)足。 4.2.7 金屬套 金屬護套分為鉛護套和皺紋鋁護套兩種。 皺紋鋁護套采用純度不小于99.6%的鋁材制造,鋁帶的伸長(cháng)率應不小于16%。焊接皺紋鋁護套焊縫內壁平整,焊縫強度須不小于鋁套強度,不得有明顯突起,不允許有圓周方向的焊縫。 4.2.8 瀝青涂層 瀝青涂層就是金屬套表面的瀝青或熱熔膠防蝕層。防腐層附著(zhù)性好,被均勻、完整地涂覆在金屬套上; 4.2.9 非金屬外護套 外護套分為單層外護套和雙層外護套。采用單層護套結構時(shí),應采用高密度聚乙烯(HDPE)、聚氯乙烯(PVC)材料 。外護套具有良好的防腐蝕、防蟻、防潮和阻燃性能;敷設于隧道內電纜非金屬外護套應采用低煙低鹵阻燃料,外護套表面都有不易脫落的連續性完好的導電層。 外護套需增加“退滅蟲(chóng)”(“Termigon”)或“退敵蟲(chóng)”防蟻護層時(shí),采用雙層護套結構,其中內層護套應采用高密度聚乙烯(HDPE)護套料,外層護套應采用“退滅蟲(chóng)”(“Termigon”) 或“退敵蟲(chóng)”防蟻護套料。 內層高密度聚乙烯護套厚度應為3.0~3.5mm,外層防蟻護套厚度應為2.0±0.1mm。內層高密度聚乙烯宜選用紅色添加劑,以示和外層防蟻護套區別。防蟻護套具有良好的抗腐蝕性(尤其是螞蟻分泌的甲酸)、耐磨性和彈性。表面具有較高的光潔度。 4.2.10 石墨半導電層 位于外護套表面有一層以石墨半導電層,半導電層均勻地包覆在外護套上。牢固的導電層作為外護套耐壓試驗時(shí)的外電極。 五、吊裝、貯存、運輸 5.1吊裝電纜應用滿(mǎn)足重量要求的起重機及鋼纜吊裝,嚴禁幾盤(pán)同時(shí)吊裝,嚴禁從高處扔下裝有電纜的電纜盤(pán),嚴禁機械損傷電纜,吊裝時(shí)不得磕碰、吊斜,起吊點(diǎn)要正確,要輕吊輕放。 5.2 電纜盤(pán)不允許平放或溜放,電纜附件應避免在露天存放,電纜及附件應避免接觸有腐蝕性的物質(zhì),應采取必要的防火措施。并有專(zhuān)人經(jīng)常巡視,防止因意外情況造成電纜及附件受到損傷。 5.3 裝在車(chē)、船等運輸工具上的電纜盤(pán)必須平穩放置,采用合適方法固定(如線(xiàn)盤(pán)托),防止互相碰撞或翻倒。 5.4 電纜盤(pán)(不論有無(wú)托架)放置的位置要平整,不得存放于大于5度的斜面上。電纜盤(pán)側板上標有“電纜盤(pán)滾動(dòng)方向”和“牽引頭拉出方向”,牽引頭拉出方向與放線(xiàn)方向一致,放線(xiàn)前,應確認無(wú)誤。 (銷(xiāo)售中心)?(Tender Quatation)?(銷(xiāo)售業(yè)務(wù)對接)

工作時(shí)間 周一至周五 :8:30-17:30 周六至周六 :9:00-12:00 聯(lián)系方式 客戶(hù)經(jīng)理Customer Manager:郭經(jīng)理 手機號碼 Mobile:13580489721(微信同號);18928822020 電話(huà)號碼Tel:86-020-82986388-8153 傳真號碼 Fax:86-020-82986949 Web郵箱( E-mail):gznycables@163.com 客服郵箱 service E-mail:1091415526@qq.com 聯(lián)系地址(總部):廣州經(jīng)濟技術(shù)開(kāi)發(fā)區永和經(jīng)濟區永豐路19號-廣州南洋電纜集團有限公司 Headquarter Address:No. 19 Yongfeng Road, Yonghe Economic Zone, Guangzhou economic and Technological Development Zone 網(wǎng)站內容均受?chē)曳杉皣H公約有關(guān)著(zhù)作權、商標權、專(zhuān)利權及其他財產(chǎn)所有權法律保護,為m.nonprofitgallery.com網(wǎng)站專(zhuān)屬。未經(jīng)投標報價(jià)中心網(wǎng)站管理人明確書(shū)面授權,任何人不得變更、轉載、復制、改動(dòng)、散布任何內容,否則以侵權論,依法追究法律責任。 |