銷(xiāo)售中心

(Tender Quatation) Sales center

|

標簽模塊

產(chǎn)品展示

BBTRZ電纜技術(shù)

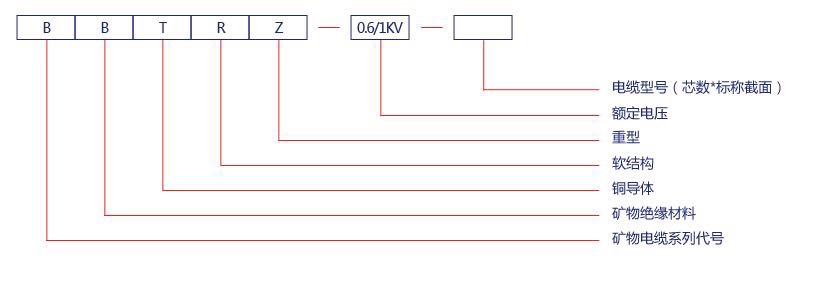

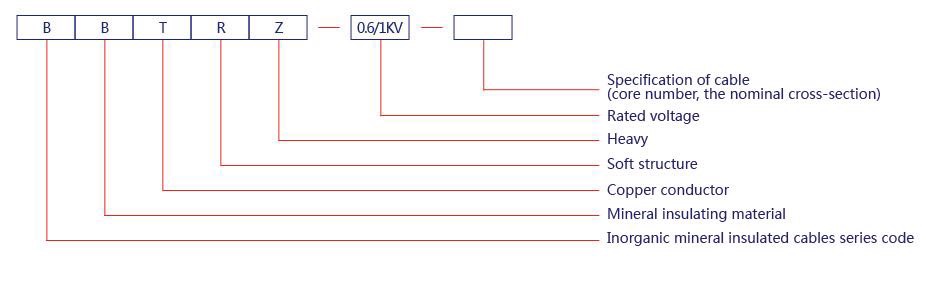

南洋電纜額定電壓 0.6/1kV礦物絕緣電纜~BBTRZ電纜技術(shù) 一、 產(chǎn)品執行標準 1.1 GB/T 2951-2008 《電纜和光纜絕緣各護套材料通用試驗辦法 》 1.2 GB/T 3048-207 《電線(xiàn)電纜電性能試驗辦法》 1.3 JG/T 313-2014 《額定電壓0.6/1kV及以下金屬護套無(wú)機礦物絕緣電纜及終端》 1.4 BS 6387-1994 《在火焰條件下張維持線(xiàn)路完整性的電纜性能要求》 1.5 BS 8491:2008《用于煙和熱控制系統及其他特定的仍在繼續的火災安全系統部件的大直徑電力電纜著(zhù)火完整性的評定方法》 二 使用條件 2.1 額定電壓0.6/1V及以下消防要求等級較高的各類(lèi)建筑物的消防系統; 2.2 大型商場(chǎng),醫院,地鐵,機場(chǎng),碼頭,航空航天,國防工程,衛星發(fā)射,中央控制中心等重要場(chǎng)所; 2.3 石油,核電站、冶金、化工、礦井、制窯等危險、惡劣、高溫環(huán)境 三、電纜型號和產(chǎn)品表示方法 3.1 耐高溫 A類(lèi)防火等級可以在950±40℃高溫下承受90分鐘維持正常通電,B類(lèi)防火等級在750℃±40℃溫度下可以持續工作90分鐘。 3.2 生產(chǎn)長(cháng)度長(cháng) 可按客戶(hù)定制長(cháng)度生產(chǎn),生產(chǎn)規格從2.5mm2-400mm2,長(cháng)度依據電纜規格和電纜盤(pán)容量可達800-10000米; 3.3 過(guò)載能力大 由于采用無(wú)機物作為絕緣材料,其耐溫點(diǎn)遠高于聚乙烯材料,電纜可以在大電流高溫下長(cháng)期運行,因而電纜的過(guò)載能力遠遠大于普通聚乙烯絕緣電纜。 3.4、使用壽命長(cháng) 所用材料均為無(wú)機物,而無(wú)機物的性能穩定,有效保護導體免受氧化作用,使用壽命為普通聚乙烯絕緣電纜的數倍以上。 3.5 安裝方便 3.5.1 礦物絕緣柔性耐火電纜柔性好,可任意盤(pán)繞在電纜盤(pán)上,保證了運輸中電纜的安全性; 3.5.2安裝方便,適宜于各種敷設方式,可依據敷設現場(chǎng)需要任意裁剪長(cháng)度; 3.6 綠色環(huán)保 產(chǎn)品由耐火絕緣層,絕緣保護層,隔氧層,無(wú)鹵低煙外護套無(wú)組成,耐火絕緣層由高絕緣性耐火云母,強力薄膜與玻璃纖維等組合制成。這些無(wú)機物不會(huì )燃燒也不會(huì )產(chǎn)生煙霧,更沒(méi)有有毒的煙霧產(chǎn)生,所以真正達到了無(wú)煙無(wú)毒不燃燒。是一種環(huán)保型電纜。 四、電纜型號和產(chǎn)品表示方法 4.1 代號表示 礦物絕緣電纜系列代號…………………………………B 礦物絕緣材料………………………………………………..B 銅導體……………………………………………………………T 軟結構…………………………………………………………...R 重型………………………………………………………………..Z 4.2 產(chǎn)品表示方法

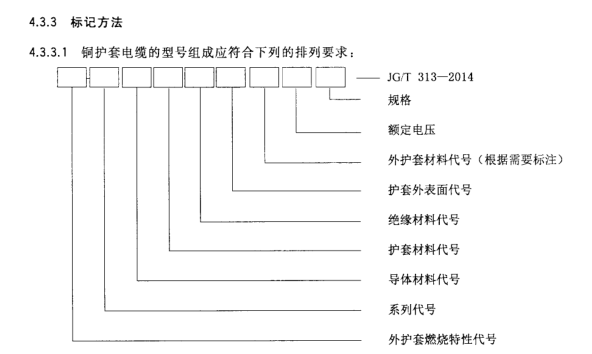

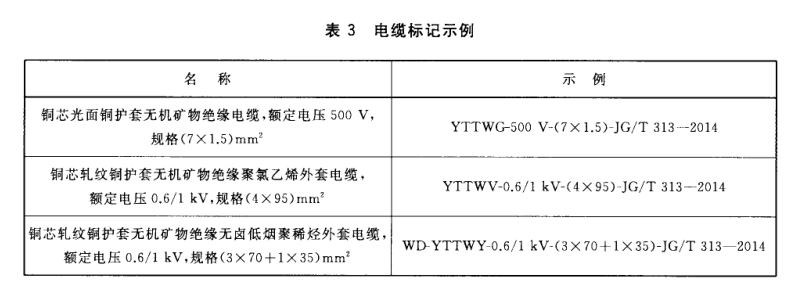

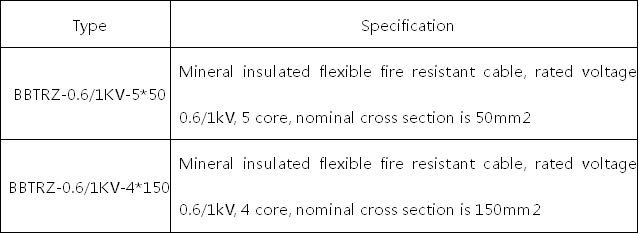

產(chǎn)品型號(礦物電纜系列代號、礦物絕緣材料、銅導體、軟結構、重型、額定電壓)、規格(芯數、標稱(chēng)截面)及標準編號表示; 4.3,產(chǎn)品型號

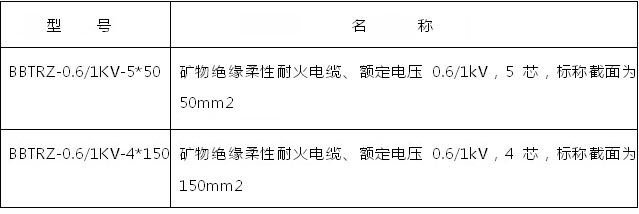

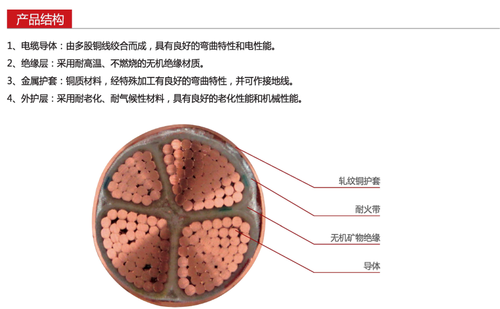

五、產(chǎn)品結構 5.1 產(chǎn)品結構示意圖

規格型號: BTTRZ-0.6/1KV-3*240+2*120mm2

規格型號: BTTRZ-0.6/1KV-3*240+2*120mm2 5.2 產(chǎn)品結構 (1) 電纜導體:由多股銅線(xiàn)絞合而成,具有良好的彎曲性能和導電性能; (2) 絕緣層:采用耐高溫,不燃燒的無(wú)機礦物絕緣材質(zhì)和耐高溫的絕緣保護層; (3) 隔氧層:在高溫下可析出水分散熱,降溫并形成隔氧保護層殼體的材料; (4) 礦物質(zhì)填充層:采用國內外先進(jìn)納米技術(shù)研制的無(wú)機礦物質(zhì)材料,具有防火、耐火、耐高溫、隔溫、隔熱等優(yōu)點(diǎn)。 (5) 外護套:采用低煙無(wú)毒或更好更高的塑型材質(zhì),在發(fā)生火災時(shí)不產(chǎn)生有害氣體,耐老化,耐腐蝕性。具有良好的抗老化性能和機械性能; YTTW、YTTWY技術(shù)

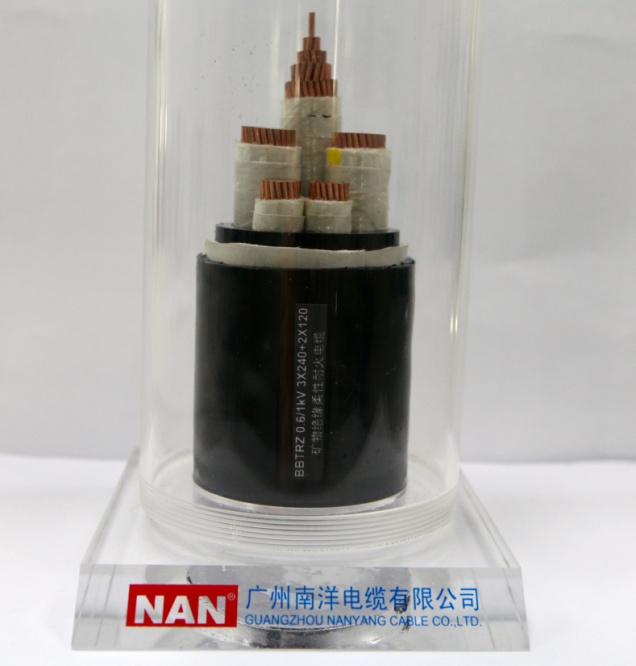

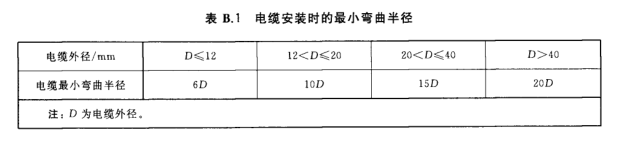

YTTW、WD-YTTWY額定電壓0.6/1KV金屬護套無(wú)機礦物絕緣電力電纜 一、執行依據及標準: GB/T 2951-2008 《電纜和光纜絕緣各護套材料通用試驗辦法 》 GB/T 3048-207 《電線(xiàn)電纜電性能試驗辦法》 JG/T 313-2014 《額定電壓0.6/1kV及以下金屬護套無(wú)機礦物絕緣電纜及終端》 BS 6387-1994 《在火焰條件下張維持線(xiàn)路完整性的電纜性能要求》 BS 8491:2008《用于煙和熱控制系統及其他特定的仍在繼續的火災安全系統部件的大直徑電力電纜著(zhù)火完整性的評定方法》 二、使用條件 2.1 額定電壓0.6/1kV及以下各類(lèi)建筑物的電力消防系統; 2.2 大型商場(chǎng),酒店,醫院,機場(chǎng),石油,化工,核電,航空航天,國防工程,衛星發(fā)射,中央控制中心等重要場(chǎng)所; 三、產(chǎn)品特點(diǎn) 3.1 制造長(cháng)度長(cháng) 傳統氧化鎂礦物絕緣電纜采用氧化鎂絕緣,受設備,生產(chǎn)工藝影響,電纜制造長(cháng)度短,長(cháng)距離安裝需要使用大量中間接頭,施工難度大電氣安全隱患多。 YTTW、WD-YTTWY金屬護套無(wú)機礦物絕緣電纜不管是單芯,還是多芯電纜,其長(cháng)度能滿(mǎn)足供電長(cháng)度需要,每根連續長(cháng)度可達1000m以上; 3.2 制造截面大 單芯電纜截面可達630mm2,多芯電纜可達240mm2; 3.3.柔軟易彎曲 具有柔性,電纜可以盤(pán)在盤(pán)上,根據電纜外徑的不同,其彎曲半徑6~20D;

3.4 載流量及過(guò)載能力大 電纜不僅載流量大,而且具有較大的過(guò)載能力。根據布線(xiàn)要示,通常電纜表面溫度≤70℃,若布線(xiàn)不可觸摸,也不與可燃建筑材料相接觸時(shí),電纜護套溫度可提高到105 ℃。過(guò)載時(shí)防火電纜長(cháng)期工作溫度可達250 ℃ 3.5 防火性能優(yōu)越,綠色環(huán)保 耐火等級不僅滿(mǎn)足國標GB12666.6A類(lèi)950-1000℃,3小時(shí)以上。且可承受消防救助時(shí)的水淋,以及火災時(shí)建筑物脫落物體對金屬護套無(wú)機礦物絕緣電纜的機械沖擊,為人群疏散以及大火救援提供極大的保障;絕緣采用無(wú)機材料,燃燒時(shí)無(wú)煙無(wú)毒,更不會(huì )發(fā)生2次污染,是真正的環(huán)保綠色產(chǎn)品; 3.6 耐腐蝕,屏蔽性能好 銅護套耐腐蝕性良好,在腐蝕性的環(huán)境下,應制作成聚烯烴外護層。由于銅護套的屏蔽,無(wú)電磁干擾,不會(huì )對信號、控制電線(xiàn)電纜傳輸的信息產(chǎn)生干擾。 3.7 使用壽命長(cháng) 耐高溫不易老化,在正常工作狀態(tài)下,它的使用壽命在80年以上。 3.8 經(jīng)濟性好,安裝施工方便 柔性防火電纜彎曲性好可裝盤(pán)供貨,方便運輸以及安裝。且可任意分割,速度快,工時(shí)短; 四 電纜型號和產(chǎn)品表示方法 4.1 代號表示 金屬護套無(wú)機礦物絕緣電纜…………………………Y 銅導體…………………………………………………T 無(wú)機礦物絕緣…………………………………………W 銅護套…………………………………………………T 縱包氬弧焊接軋紋……………………………………ZW(可省略) 聚氯乙烯護套…………………………………………V 聚乙烯或聚烯烴護套…………………………………Y 4.2 產(chǎn)品表示方法

產(chǎn)品型號(無(wú)機礦物絕緣電纜系列代號、銅導體、銅護套、無(wú)機礦物絕緣、額定電壓)、規格(芯數、標稱(chēng)截面)及標準編號表示; 4.3產(chǎn)品型號

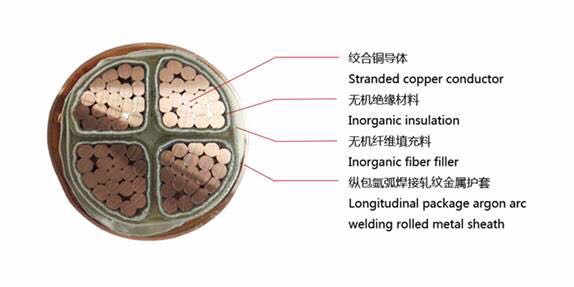

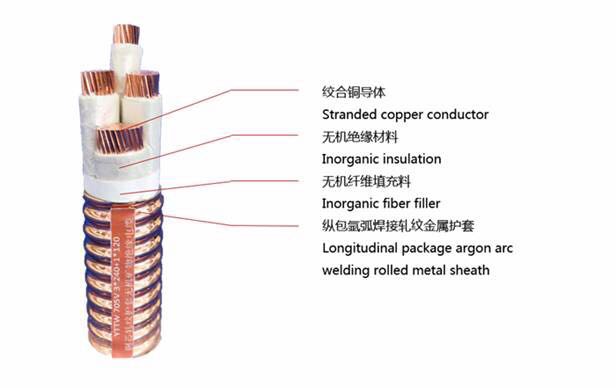

五、產(chǎn)品結構 5.1 產(chǎn)品結構示意圖

規格型號: YTTW-0.6/1KV-4*240mm2

規格型號: YTTW-0.6/1KV-3*240+1*120mm2

規格型號: YTTWY-0.6/1KV-4*240mm2 5.2 產(chǎn)品結構 5.2.1 電纜導體:導體由多股銅線(xiàn)絞合而成,具有良好的彎曲性能和導電性能; 5.2.2 絕緣層:高絕緣性耐火云母和強力薄膜與玻璃纖維組合制成耐火絕緣層; 5.2.3 填充層:采用無(wú)機礦物纖維材料,能耐高溫,并能有效隔溫,隔熱; 5.2.4 金屬護套:為銅質(zhì)材料,縱包氬弧焊接金屬護套,經(jīng)過(guò)特殊加工,具有良好的彎曲性能,并可作接地線(xiàn); 5.2.5 外護套:依據訂制要求,可直接生產(chǎn)成金屬護套或PVC,PE外護套。PE外護套采用低煙無(wú)毒的塑性材質(zhì),有良好的防腐蝕特性; 礦物電纜產(chǎn)品結構

礦物絕緣電纜技術(shù)性能 1 YTTW、WD-YTTWY礦物絕緣電纜技術(shù)要求 1.1 導體 1.1.1 導體采用優(yōu)質(zhì)無(wú)氧銅桿,其組成、性能及外觀(guān)符合GB/T 3956-2008中第1種和第2種導體規定。 1.1.2 YTTW金屬護套無(wú)機礦物絕緣電纜導體:10~50mm2采用絞合圓形導體,大截面導體采用預成型扇形緊壓結構。 1.1.3 導體表面光潔,無(wú)油污,無(wú)損傷屏蔽及絕緣的毛刺、銳邊,無(wú)凸起或斷裂的單線(xiàn)。 1.2 絕緣 1.2.1 YTTW金屬護套無(wú)機礦物絕緣電纜絕緣材料采用950~1000℃無(wú)機礦物合成云母帶。其性能符合GB/T 5019.10-2009中規定。 1.2.2 每根導體上應繞包無(wú)機礦物合成云母帶絕緣,其平均厚度不應小于標準JG/T 313-2011中規定的絕緣標稱(chēng)厚度的90%。 1.2.3 電纜的絕緣電阻(MΩ)與電纜長(cháng)度的乘積不應小于100Ω·km。當電纜長(cháng)度小于100m時(shí),測量的絕緣電阻不應低于1000MΩ。 1.3 金屬護套 1.3.1 護套材料應為普通退火銅或銅合金,護套應符合GB/T 2059-2008中T2或TU2牌號帶材的規定。 1.3.2 護套的平均厚度不應小于JG/T 313-2011中規定的標稱(chēng)厚度。 1.3.3 護套外徑的平均值應符合JG/T 313-2011中規定的電纜標稱(chēng)外徑,外徑公差為電纜標稱(chēng)外徑的±5%。 1.3.4 銅護套在20℃的直流電阻不應大于JG/T 313-2011中20℃銅護套計算電阻的110%。 1.4外護套(適用于WD-YTTWY) 1.4.1護套采用90℃無(wú)鹵低煙阻燃型護套料,表面光潔、圓整,其標稱(chēng)厚度和性能符合標準規定,任一點(diǎn)最小厚度不小于標稱(chēng)值得80%。 1.5產(chǎn)品結構示意圖

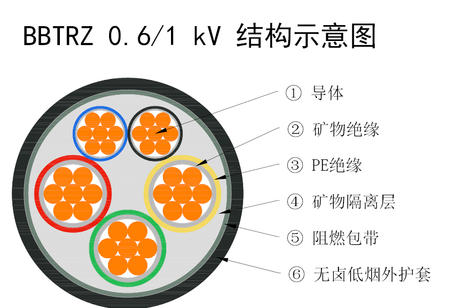

2BBTRZ礦物絕緣電纜技術(shù)要求 2.1 導體 2.1.1 導體采用優(yōu)質(zhì)無(wú)氧銅桿,其組成、性能及外觀(guān)符合GB/T 3956-2008中第1種和第2種導體規定。 2.1.2 礦物絕緣柔性耐火電纜導體:10~35mm2采用絞合非緊壓圓形導體,50mm2及以上導體采用緊壓圓形結構。 2.1.3 導體表面光潔,無(wú)油污,無(wú)損傷屏蔽及絕緣的毛刺、銳邊,無(wú)凸起或斷裂的單線(xiàn)。 2.2 絕緣 2.2.1 礦物絕緣柔性耐火電纜絕緣由礦物絕緣層和PE層組成。其中礦物絕緣層采用950℃~1000℃耐高溫無(wú)機礦物合成云母帶,其性能符合GB/T 5019.10-2009中規定。 2.2.2 每根導體上應繞包耐高溫無(wú)機礦物合成云母帶絕緣、擠包PE層,其平均厚度不應小于標準Q/GZNY 11-2013中規定的絕緣標稱(chēng)厚度。 2.2.3 100m及以上長(cháng)度的電纜的絕緣電阻(MΩ)與電纜長(cháng)度的乘積不應小于100Ω·km。當電纜長(cháng)度小于100m時(shí),測量的絕緣電阻不應低于1000MΩ。 2.3 礦物隔離層 2.3.1 礦物隔離層采用防火性能較好的隔氧泥材料。 2.3.2 礦物隔離層最薄點(diǎn)厚度不應小于Q/GZNY 11-2013中規定的標稱(chēng)厚度的90%-0.1mm。 2.4外護套 2.4.1外護套采用90℃無(wú)鹵低煙阻燃型護套料,表面光潔、圓整,其標稱(chēng)厚度和性能符合標準規定,任一點(diǎn)最小厚度不小于標稱(chēng)值得85%-0.1mm。 2.5產(chǎn)品結構示意圖

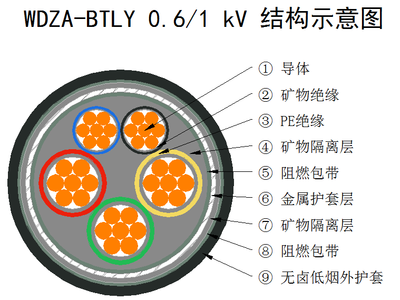

3.BTLY礦物絕緣電纜技術(shù)要求 3.1 導體 3.1.1 導體采用優(yōu)質(zhì)無(wú)氧銅桿,其組成、性能及外觀(guān)符合GB/T 3956-2008中第1種和第2種導體規定,銅純度≥99.9%。 3.1.2 礦物絕緣柔性耐火電纜導體:10~35mm2采用絞合非緊壓圓形導體,50mm2及以上導體采用緊壓圓形結構。 3.1.3 導體表面光潔,無(wú)油污,無(wú)損傷屏蔽及絕緣的毛刺、銳邊,無(wú)凸起或斷裂的單線(xiàn)。 3.2 絕緣 3.2.1 礦物絕緣柔性耐火電纜絕緣由礦物絕緣層和PE層組成。其中礦物絕緣層采用950℃~1000℃耐高溫無(wú)機礦物合成云母帶,其性能符合GB/T 5019.10-2009中規定。 3.2.2 每根導體上應繞包耐高溫無(wú)機礦物合成云母帶絕緣、擠包PE層,其平均厚度不應小于標準Q/GZNY 15-2018中規定的絕緣標稱(chēng)厚度。 3.2.3 100m及以上長(cháng)度的電纜的絕緣電阻(MΩ)與電纜長(cháng)度的乘積不應小于100Ω·km。當電纜長(cháng)度小于100m時(shí),測量的絕緣電阻不應低于1000MΩ。 3.3 礦物隔離層 3.3.1 礦物隔離層采用防火性能較好的隔氧泥材料。 3.3.2 礦物隔離層最薄點(diǎn)厚度不應小于Q/GZNY 15-2018中規定的標稱(chēng)厚度的85%-0.1mm。 3.4金屬護套層 3.4.1金屬護套層采用5000系列鋁合金帶材料。 3.4.2金屬護套帶材寬度、搭蓋率、軋紋深度符合Q/GZNY 15-2018中規定。 3.5 礦物隔離層 3.5.1 礦物隔離層采用防火性能較好的隔氧泥材料。 3.5.2 礦物隔離層最薄點(diǎn)厚度不應小于Q/GZNY 15-2018中規定的標稱(chēng)厚度的85%-0.1mm。 3.6外護套 3.6.1外護套采用90℃無(wú)鹵低煙阻燃型護套料,表面光潔、圓整,其標稱(chēng)厚度和性能符合標準規定,任一點(diǎn)最小厚度不小于標稱(chēng)值得85%-0.1mm。 3.8產(chǎn)品結構示意圖

BBTRZ cable

BBTRZ rated voltage 0.6/1kV mineral insulated flexible cable refractory product introduction BBTRZ rated voltage 0.6/1kV mineral insulated flexible cable refractory product introduction 1 Product standard 1.1 GB/T 2951-2008 Common test methods for insulating materials of cable and optical cable insulation 1.2 GB/T 3048-207 Test methods for electrical properties of electric wires and cables 1.3 JG/T 313-2014 Metal sheathed inorganic mineral insulated cables and terminals with rated voltage 0.6/1KV and below 1.4 BS 6387-1994 Cable performance requirements for maintaining line integrity under fire 1.5 BS 8491:2008 Method for assessment of fire integrity of large diameter power cables for use as components for smoke and heat control systems and certain other active fire safety systems 2 Use conditions 2.1 Rated voltage 0.6/1V and below the fire protection requirements of the higher level of all types of buildings fire system; 2.2 Large shopping malls, hospitals, subways, airports, docks, aerospace, defense engineering, satellite launch, central control center and other important places; 2.3 Oil, nuclear power station, metallurgy, chemical industry, mine, kiln and other dangerous, harsh, high temperature environment 3 Product Features 3.1 Resistant to high temperature Class A fire protection rating can be 950 ±40 degrees Celsius under high temperature to withstand 90 minutes to maintain normal power, B fire rating at 750±40 degrees Celsius temperature can continue to work for 90 minutes. 3.2 Long production length Can be customized according to customer length of production, specifications from 2.5mm2 to 400mm2, length based on cable specifications and cable tray capacity of up to 8000 to 800 meters; 3.3 Overload capacity Due to the use of inorganic material as insulation material, its temperature resistance point is much higher than the polyethylene material , the cable can run at high current and high temperature, so the cable overload capacity is far greater than the ordinary polyethylene insulated cable. 3.4 Long service life Materials used are inorganic materials, and inorganic stable performance, effectively protect the conductor from oxidation, service life for ordinary polyethylene insulated cables of several times over. 3.5 Convenient installation 3.5.1 Mineral insulated flexible fireproof cable has good flexibility, can be coiled on the cable tray, to ensure the safety of transportation in cable; 3.5.2 Installation is convenient, suitable for all kinds of laying way, can be based on the laying of the scene need any cutting length; 3.6 Green environmental protection The product is composed of a refractory insulation layer, an insulating protective layer, an oxygen separation layer, a non halogen low smoke outer sheath, and the refractory insulating layer is made of high insulating refractory mica, strong film and glass fiber. These inorganic compounds will not burn and will not produce smoke, no more toxic smoke generated, so it really reached a non toxic and non burning. Is a kind of environmental protection cable . 4 Cable type and description 4.1 Code Mineral insulated cables series code…………………………………………………...B Mineral insulating material…………………………………………………………………..…B Copper conductor…………………………………………………………………………….……..T Soft structure…………………………………………………………………………………………..R heavy…………………………………………………………………………………………………….…Z 4.2 Product representation method

Description of product model (Mineral insulated cables series code,Mineral insulating material,Copper conductor,soft structure,heavy, rated voltage), specifications (core, the nominal cross-section) and standard code. 4.3, Type

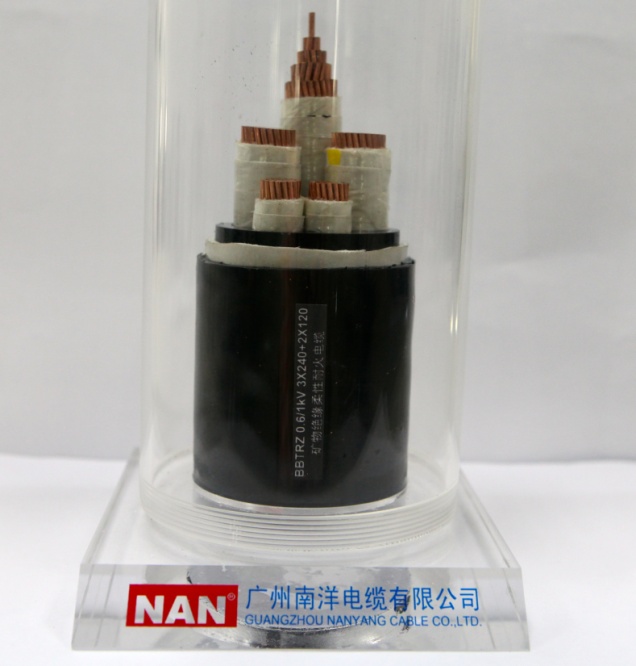

5 Product structure 5.1 Schematic diagram of product structure

Specification Model: BTTRZ-0.6/1KV-3*240+2*120mm2

Specification Model: BTTRZ-0.6/1KV-3*240+2*120mm2 5.2 Product Structure (1) Cable conductor: by multi strand copper wire twisted, with bending performance and good electrical conductivity; (2) Insulation: the use of high temperature resistant, non burning inorganic mineral insulation material and high temperature insulation protection layer; (3) Oxygen barrier layer: moisture and heat can be separated from the heat insulation layer, and the material of the shell of the oxygen insulation protective layer is formed; (4) Mineral filled layer: The product adopts the inorganic mineral material which is developed by domestic and foreign advanced nanometer technology. has the advantages of fire prevention, fire resistance, high temperature resistance, heat insulation and so on. (5) Outer sheath: The product is made of non-toxic or low smoke and better plastic material, no harmful gas is produced when fire occurs, resistance to aging, corrosion resistance. Has good ageing resistance and mechanical properties; WD-YTTWY cable

YTTW, WD-YTTWY Rated voltage 0.6/1KV and below metal sheath inorganic mineral insulated cable product introduction 1 Product standards GB/T 2951-2008 Common test methods for insulating materials of cable and optical cable insulation GB/T 3048-207 Test methods for electrical properties of electric wires and cables JG/T 313-2014 Metal sheathed inorganic mineral insulated cables and terminals with rated voltage 0.6/1KV and below BS 6387-1994 Cable performance requirements for maintaining line integrity under fire conditions 2 use conditions 2.1 Rated voltage 0.6/1KV and below various types of buildings fire fighting system; 2.2 large shopping malls, hospitals, airports, petroleum, chemical, nuclear power, aerospace, national defense engineering, satellite launch, central control center and other important places; 3 Product features 3.1 Long manufacturing length Traditional magnesium oxide mineral insulated cables using magnesium oxide insulation, Affected by equipment, production process, cable manufacturing length is short, long distance installation requires the use of a large number of intermediate joints, construction difficulty big electrical safety hazards. The metal sheath inorganic mineral insulated cable whether it is single core or multi-core cable, its length can meet the needs of power supply, and the continuous length of each cable is up to 1000m; 3.2 Large manufacturing cross section The metal sheath inorganic mineral insulated cable whether it is single core or multi-core cable, its length can meet the needs of power supply, and the continuous length of each cable is up to 1000m; 3.3 Soft and easy to bend With a flexible cable can be set on the plate, the bending radius of 6-10 times diameter; 3.4 Rating current and overload capacity The cable is not only large rating current, but also has a large overload capacity. According to wiring should be shown, usually cable surface temperature is less than or equal to 70 DEG C, if the wiring can not touch, nor with the combustible building materials contact, cable sheath temperature can be increased to 105 degrees Celsius. Overload, the long-term working temperature of fire resistant cable up to 250 3.5 Excellent fire performance, green environmental protection Refractory grade is not only to meet the national standard GB12666.6 class A, Run 950-1000 degrees Celsius, more than 3 hours. And can withstand fire rescue when pouring water, Mechanical shock of the metal sheath inorganic mineral insulated cables when the buildings fall off in fire, for the crowd evacuation and fire rescue provides great protection; insulation adopts inorganic materials, burning smoke-free non-toxic, but will not happen twice pollution. it is the real green environmental protection products; 3.6 Corrosion resistance and good shielding performance Corrosion resistance of copper sheath is good, in the corrosive environment, should be made into polyolefin outer protective layer. Due to the shielding of the copper sheath, no electromagnetic interference, does not have the interference to the signal, the control wire and cable transmission information. 3.7 Long service life Resistance to high temperature is not easy to aging, in the normal working state, It's service life in more than 80 years. 3.8 Good economy, convenient installation and construction Flexible fireproof cable with good bending performance, convenient transportation and installation. And can be arbitrarily split, fast installation speed, short working hours; 4 Cable type and description 4.1 Code Copper conductor……………………………………………………………. ………………….…..T Inorganic mineral insulation……………………………………………………………………..W Longitudinal package argon arc welding rolled copper sheath………………..T PVC insulation……………………………………………………………………………………………V PE insulation………………………………………………………………………………………………Y 4.2 Product representation method

Description of product model (inorganic mineral insulated cables series code, Copper conductor, copper sheath, inorganic mineral insulated, rated voltage), specifications (core, the nominal cross-section) and standard code. 4.3 Type

5 Product structure 5.1 Schematic diagram of product structure Specification Model: YTTW-0.6/1KV-4*240mm2

Specification Model: YTTW-0.6/1KV 3*240+1*120mm2

Specification Model: YTTWY--0.6/1KV -4*240mm2 5.2 Product structure 5.2.1 Cable conductor: conductor by multi strand copper wire twisted possesses good flexural properties and good electrical conductivity; 5.2.2 Insulation: high insulating refractory mica and strong film and glass fiber composite refractory insulation layer, 5.2.3 Fill layer: The product adopts inorganic mineral fiber materials, high temperature resistance, and can effectively heat insulation, thermal insulation; 5.2.4 Metal sheath: copper material, vertical packages argon arc welding metal sheath, through special processing, with good bending performance, and can be used for grounding wire; 5.2.5 Outer sheath: according to the custom requirements, can be directly produced metal sheath or PVC, PE outer sheath. PE outer sheath is made of low smoke and nontoxic plastic material. It has good corrosion resistance; (銷(xiāo)售中心)?(Tender Quatation)?(銷(xiāo)售業(yè)務(wù)對接)

工作時(shí)間 周一至周五 :8:30-17:30 周六至周六 :9:00-12:00 聯(lián)系方式 客戶(hù)經(jīng)理Customer Manager:郭經(jīng)理 手機號碼 Mobile:13580489721(微信同號);18928822020 電話(huà)號碼Tel:86-020-82986388-8153 傳真號碼 Fax:86-020-82986949 Web郵箱( E-mail):gznycables@163.com 客服郵箱 service E-mail:1091415526@qq.com 聯(lián)系地址(總部):廣州經(jīng)濟技術(shù)開(kāi)發(fā)區永和經(jīng)濟區永豐路19號-廣州南洋電纜集團有限公司 Headquarter Address:No. 19 Yongfeng Road, Yonghe Economic Zone, Guangzhou economic and Technological Development Zone 網(wǎng)站內容均受?chē)曳杉皣H公約有關(guān)著(zhù)作權、商標權、專(zhuān)利權及其他財產(chǎn)所有權法律保護,為m.nonprofitgallery.com網(wǎng)站專(zhuān)屬。未經(jīng)投標報價(jià)中心網(wǎng)站管理人明確書(shū)面授權,任何人不得變更、轉載、復制、改動(dòng)、散布任何內容,否則以侵權論,依法追究法律責任。 |